Chetaah takes off

Cheetah

After we had gained some experience with the first functional model, it was time to tackle the next vehicle. Gerd wanted a fully shuttered, muscle-powered vehicle with an auxiliary motor. I wanted a pure electric vehicle that could be built as a curve tilt or rigid tricycle. We decided to build the basic form for both vehicles. After that, everyone should be able to design the vehicle according to their wishes. We started with design work. To find the design, we made 1:5 scale models out of Styrodur.

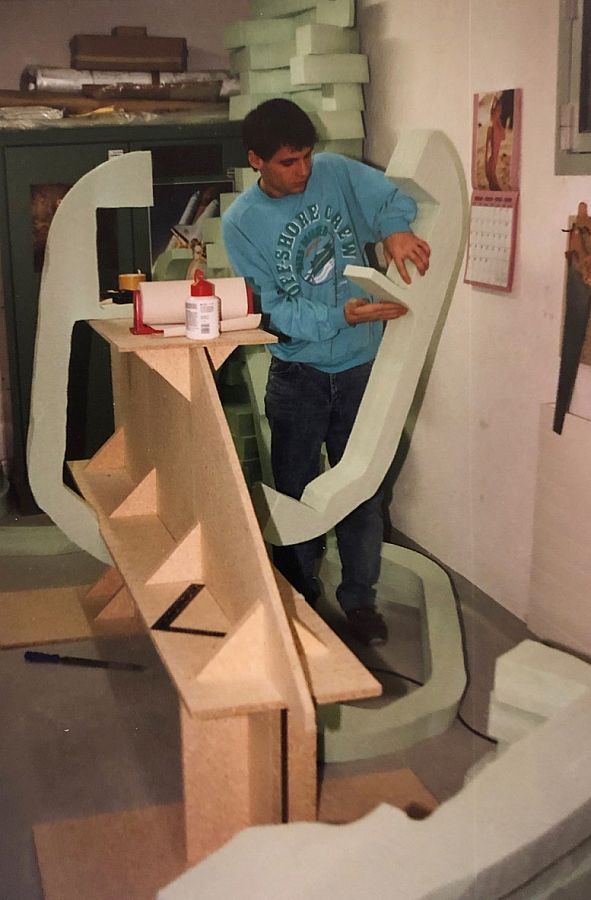

To investigate the aerodynamics, we built a wind tunnel. We converted the drive motor of the first test vehicle directly into the drive of the wind tunnel. A propeller was found in the attic (with simple material we built a balancing track) to reduce the turbulence. At least measurements up to 60km/h wind speed were possible, which gave us an impression of whether the aerodynamic quality of the vehicle was rather better or rather worse. We cut the finally selected model into slices to project them on the wall with an overhead projector and transferred them to 10 cm thick styro plates, which were screwed onto a wooden frame.

This 1:1 model was sanded to size, covered with epoxy resin and glass fibre mats, filled and fine sanded. Three months of sanding were necessary to have a perfect shape. In the meantime I worked myself deeper into the processing of epoxy resin and different fabrics. Carbon, Keflar and glass fibre were tested. Test specimens were created, the forces measured, the fracture behaviour examined. I was fascinated by how the fibres could be placed exactly along the lines of force in a construction. I got support and was able to exchange ideas with some plastics specialists and deepen my knowledge. Unfortunately, I didn't follow the applicable processing regulations enough, which was to come back to haunt me later. I will come back to this later.

Move to Andelfingen

I had a good relationship with my neighbours. I lived with my wife in Seuzach, at Stadlerstrasse 59, and designed in my study. I put the results into practice downstairs in the rented craft room. One evening - I had just finished laminating the master model - when three neighbours came into the craft room one after the other: What stings in the nose? Was it poisonous? From my point of view at the time, it wasn't - which later turned out to be a misinterpretation. Nevertheless, it seemed necessary to find another workshop for my project, which would take many months. As I had no money to pay for another workshop, I asked my father if he would let me use his garage. I estimated that I would need it until "March 91". My father immediately said yes and put his car outside. It turned out that I could only move out of the garage again in March 95. The original mould was completed in Andelfingen. The construction of the negative mould took some time because the individual layers could only be applied very slowly. So I laminated with the help of Gert, but my mother and father also came regularly to help me with one of the countless layers. In the summer of '91, we had reached the point where the negative mould could be demoulded and I could sit down for the first time to check the mass. A great moment after all the tedious hours. Two former classmates, Klaus and Christian Ent helped me to build the mould into a metal cage that could be turned like a chicken on the grill to better laminate the actual mould.

The fabric plan was made and within one day the complete fuselage of Cheetah was made. In a second day all the interior fittings were cut out and glued in and everything was covered with different fabrics. After just over 6 months of work, we had our first hull in our hands.

First test drives

A motorbike telescopic fork was installed, a first rear axle was created with sheet metal and provisional controls were fitted. Meanwhile, Beno Jäckle had built the inverter, defined the motor, bought the batteries and prepared the wiring. One weekend, the vehicle was made ready to drive in our garage and on a sunny autumn day - about 1 year after the start of construction - the first test drives were undertaken. Cheetah drove and covered the first metres. We reached about 45 km/h. Acceleration behaviour, final speed and especially energy consumption did not match our expectations at all. Beno furrowed his brow and checked several times that the gauges were working correctly. That evening he went home very thoughtful, and finally had to admit that his drive could not be optimised in a reasonable time to meet my expectations. Beno signed off from the project team.

A new drive concept is being evaluated

What to do? Cheetah needed a strong, efficient drive. I got in touch with Josef Brusa and Axel Krause of the BRUSA company. All the cars that were in front at the Tour de Sol rode with their drive. So I decided on an Asyncron controller with a maximum voltage of 140 V and 21 kW peak power. I bought the controller and motors from BRUSA, NiCd cells from Panasonic. I gathered information from various TdS participants, including Axel Krause and Fredy Lüthy, who were both using this principle. It took another 9 months until everything was installed in the Cheetah.

Exhibition Auto Salon Geneva 92

In winter I entered Cheetah and the whole team in the Tour de Sol 92. We wanted to know

how well we would do against the competition. In the course of this, I also registered us for the Geneva Motor Show. A name had to be found: "Powel" - consisting of power and electric was chosen as the group name. Cheetah had not yet been driven with the BRUSA drive. But now the goal was to get the car ready for the fair. Of course, time was short. Next to the exhibit, the name was coined in the meantime: My brother Jürg explained to me: "Cheetah means cheetah in German. The cheetah is the fastest land animal. It reaches over 120 km/h in a sprint. It runs out of energy after a relatively short time. For me, this fits perfectly with the vehicle under construction."

As I read in the exhibition regulations, we also had to provide the exhibition stand ourselves. I enquired with my neighbour Gisela Grob, from whom I knew that her sister organised the garden furniture exhibitions for her father. She let me have her stand - not the normal stand, they needed that for their own exhibition, but the reserve stand, consisting of a brown carpet and a pink back wall. Some drawings, construction plans and a showcase with some components completed the whole exhibition. Certainly we didn't get the maximum points in terms of the design of our stand.

After we had set up everything in Geneva, we looked at our work - as well as the stands of our competitors: Something was missing... Our vehicle was completely in the dark. We had simply forgotten the lights! Fortunately, there was just enough time to drive to the hardware store to organise some headlights. Overnight, my wife and I screwed the headlights wherever we could and stood the other day in our best clothes, now half-lit by whatever halogen headlights we could find. The press days could begin.

Press Days in Geneva

Cheetah and we got attention, and how!

Cheetah was a cross between a car and a motorbike, had a very futuristic shape and was absolutely new. Many reporters wanted to cover it. Several TV crews came and wanted a report. I felt quite overwhelmed, but inevitably had to go through it. There were also interviews in French and English - I should have paid more attention at school.

Designers discussed design with me. The person next to me on the stand told me that he had an important position in an Italian design company.

Some managers in suits came by and made fun of my vehicle: a glider without wings, not a car, but not a motorbike either, nothing that could be used for anything. They went on to the next stand.

A short time later, someone came by who was full of praise: a completely new kind of mobility. A minimum of energy consumption, coupled with a breathtaking look and very good performance data. He was also very taken with the built-in safety concept. We arranged to meet again at a later date. He said his team would have to see it.

At that time, he showed up with the very people who had made fun of Cheetah before. He had me explain the concept of the vehicle and added that this was exactly the kind of thinking he would like to have in his team. All the suits nodded complacently. After the presentation was over, he thanked me in a very friendly way, assured me that I could work for him at any time and pressed his business card into my hand: It said: Heiko Barske, Head of Research at the VW Group.

I got offers to buy the Cheetah. Unfortunately, that wasn't possible, it wasn't finished yet... Several wanted to produce the vehicle in series or give me money to set up production. Again, I had to say no - I had no idea how much money a series production of the vehicle would have needed. I had not yet travelled a metre with the selected drive. I couldn't be bothered with things, I first had to get my Cheetah to drive and then I wanted to take part in the Tour de Sol. These were my next goals