The first large order – production is expanded

Initially we built between 200 and 300 vehicles per year. Within three months, we had to scale up production to 1500 vehicles per year. A huge effort was ahead of us. We went through all the suppliers.

Some of them were not set up to handle large production runs. Our chassis producer in the Czech Republic, Mr. Paducha, could produce a maximum of 20 chassis per week. But we needed up to 100 chassis to fulfil the order. On my travels, I had met the chassis manufacturer Verlicci in Italy. He produced for all the well-known motorbike manufacturers, including Honda, BMW and Ducati. The old boss was very sympathetic to me. He didn't speak a word of German, and I didn't speak a word of Italian. But we still got along very well. His right hand, his toolmaker, had long since retired. But he still came to work every day to look after his machines and his people. His machines: There were over 20 robotic welding centres. It was an impressive production with a top level of accuracy. Among other things, the chassis for the legendary Ducati Monster were built there. I wanted to have my chassis produced there! We travelled to Italy, but in the meantime the old patron had handed over the management to his son. The toolmaker also stopped showing up for work. Nevertheless, we signed a contract, and they made prototypes - of the highest quality. We were going to visit them at the national motorbike show in Milano in September to discuss some details: Delivery quantity, test reports, packaging units. To our surprise, the Verlicci stand was not manned by the people we knew. But they seemed to have been waiting for us, and all details were discussed. I travelled back to Switzerland with mixed feelings. When my buyer tried to call Verlicci a few weeks later to inquire about the status of the project, the mail and phone lines were dead. The company had filed for bankruptcy in the meantime! The only thing left to do was to talk to our old chassis supplier Patucha: We needed as many chassis from him as he could produce until we found a new producer. He gave everything and produced around the clock. It was too much! His workshop burnt down! Someone had been inattentive and had heated the old wood stove too much.

What to do? Paducha assured us that he would continue production in his burnt-down workshop. We urgently needed an additional supplier. Through our contacts, we met a company that mainly worked for the furniture industry. In a short time, production was set up there - also with the help of the old supplier. There is nothing like a good network of contacts.

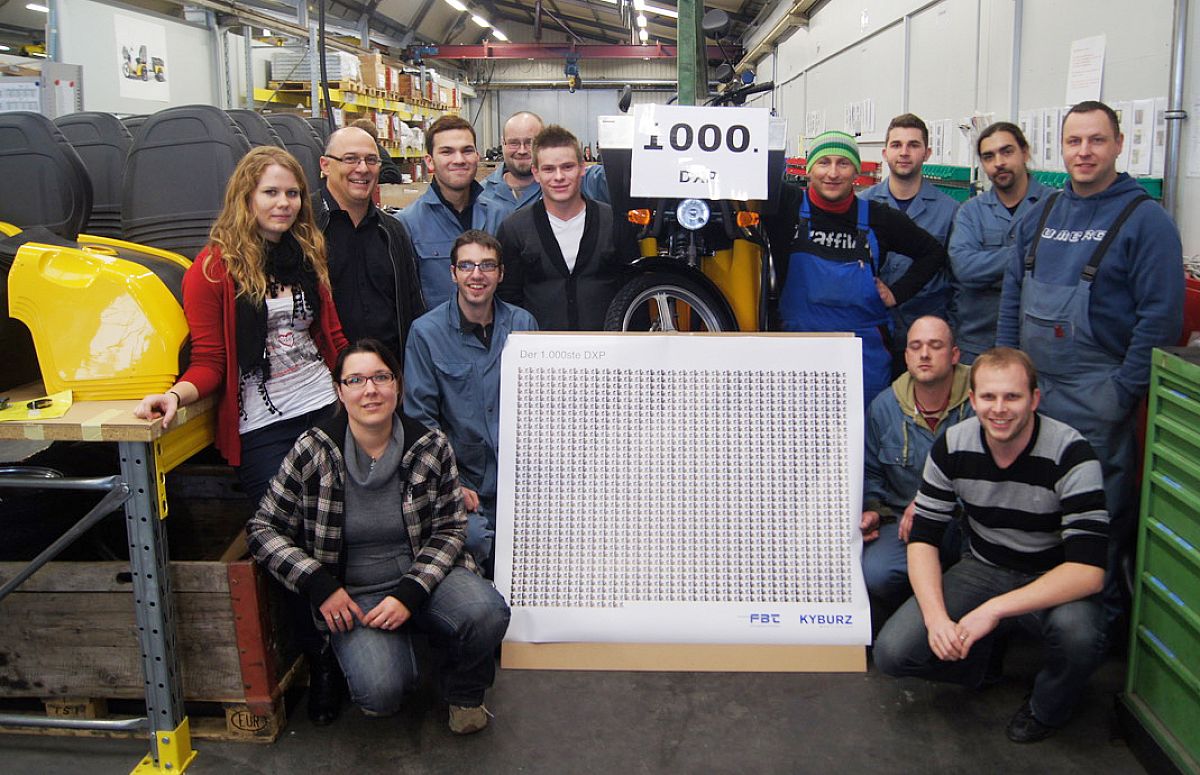

Initially, we outsourced production to FBT in Thörigen, a subsidiary of HESS in Bellach, known for its buses. We signed a contract for 3 years.

Initially, we produced postal vehicles at our premises in Freienstein and at the same time built up the larger production facility in Thörigen. After 6 months, this was running at full capacity. We were able to concentrate on the senior citizens' vehicles again.

I learned from this:

- Everything is possible, but you still have to watch your limits.

- If you treat suppliers as partners, the cooperation is terrific.

- Having a partner produce can help both.